欧标H型钢是一种截面面积分配更加优化、强重比更加合理的经济断面高效型材,因其断面与英文字母"H"相同而得名。由于H型钢的各个部位均以直角排布,因此H型钢在各个方向上都具有抗弯能力强、施工简单、节约成本和结构重量轻等优点,已被广泛应用。

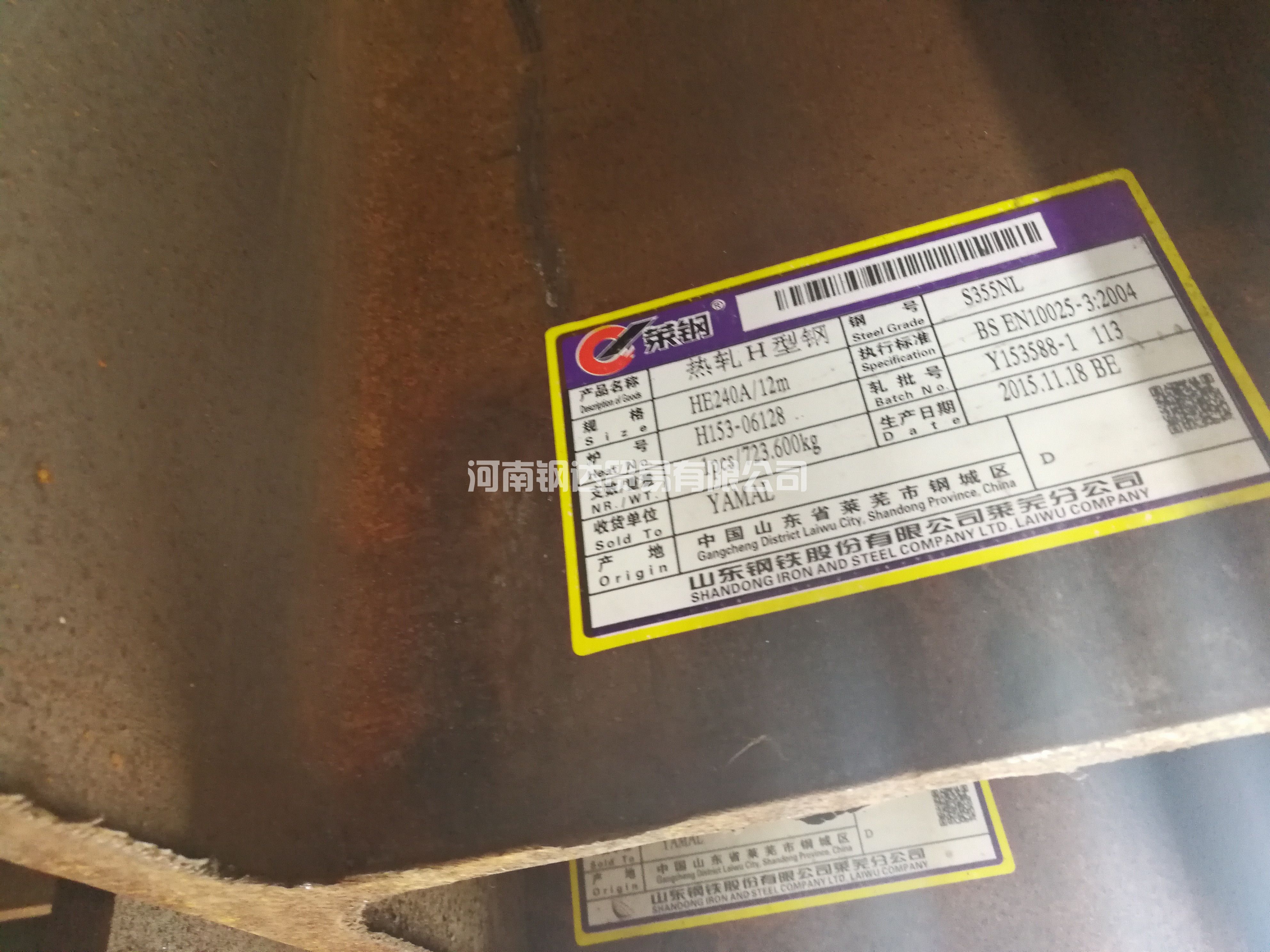

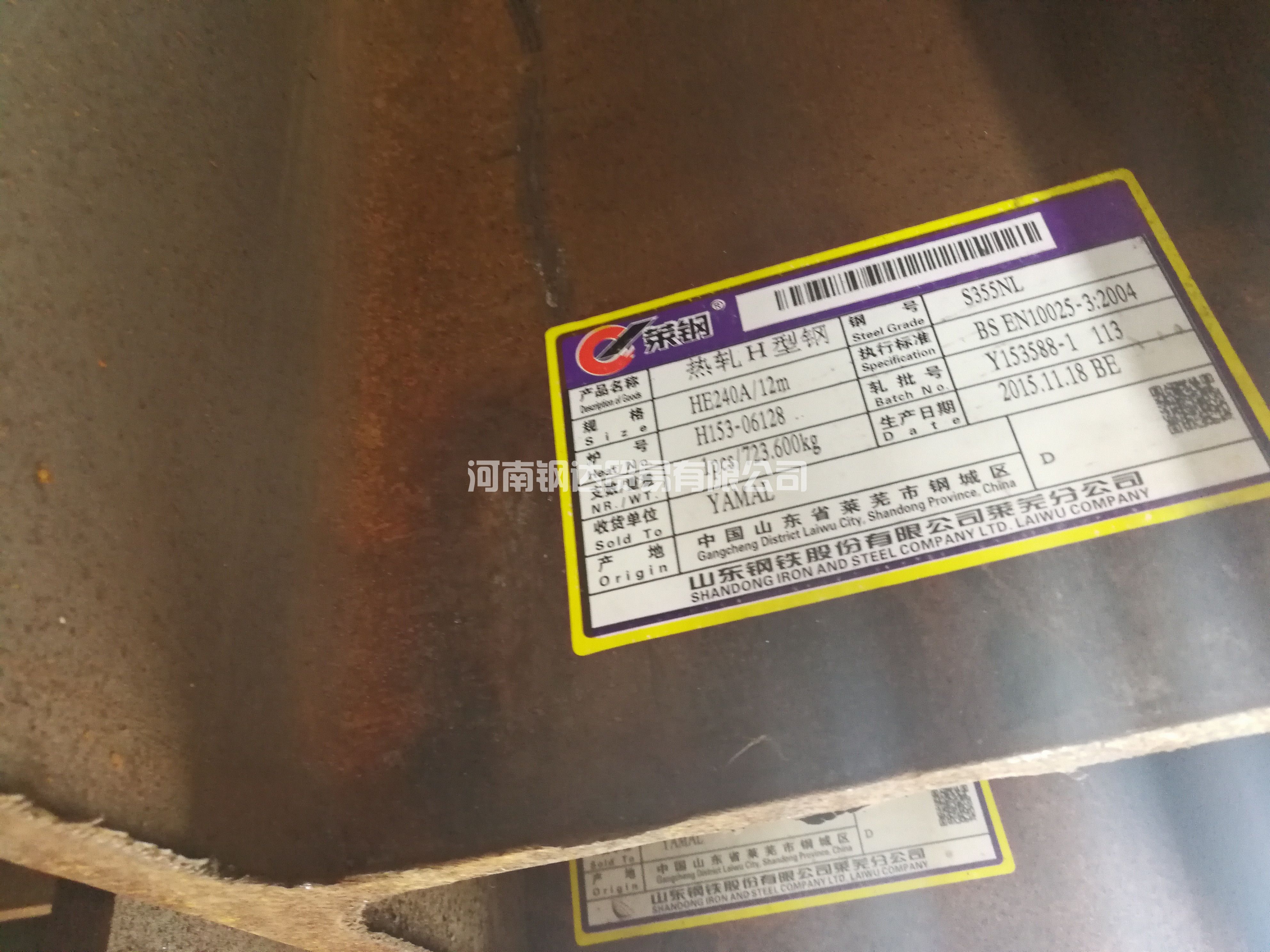

欧标型钢为欧标系列H型钢,应用于各种钢结构建筑领域,海洋工程领域,能源领域。可供欧标角钢,欧标槽钢,欧标H型钢,也应用于海洋石油平台整体结构建造领域,LNG,炼油厂等模块钢结构。

1.规格执行标准:BS EN 10365-2017 替换老标准 EN10034-1993、

2.材质执行标准:

2.1EN10025-2 结构钢的热轧产品 第二部分:非合金结构钢的技术供货条件

材质:S235JR/J0/J2、 S275JR/J0/J2、 S355JR/J0/J2/K2、 S450J0

2.2EN 10025-3 结构钢的热轧制品 第三部分:正火/正火轧制可焊接细晶粒结构钢的交货技术条件

材质: S275N/NL、 S355N/NL、 S420N/NL、S460N/NL

2.3EN 10025-4 结构钢热轧产品 第四部分 :热机械轧制可焊接细晶粒结构钢交货技术条件

材质: S275M/ML、 S355M/ML、 S420M/ML、S460M/ML

2.4EN 10025-5 结构钢热轧产品 第五部分 :改进型乃大气腐蚀结构钢交货技术条件

材质: S235J0W/J2W、 S355J0WP/J2WP、 S355J0P/J2W/K2W4 分类和标记

3 欧标型钢分类:

— 平缘工字钢 IPEAA80-750 Parallel flange I sections IPE;

— 宽翼缘H型钢 HE100AA-HE1000 Wide flange beams HE;

— 超宽翼缘H型钢 HL920-1100 × 344-607 HLZ 1000A B C D Extra wide flange beams HL and HLZ;

— 平缘H型钢 HD260-400 × 54,1-1299 Wide flange columns HD;

— 宽翼缘承重柱H 型钢 HP200-400 × 43-231 UBP 203-356 × 203 -368× 45-174Wide flange bearing piles HP and UBP;

— 英标H型钢 UB 127-1016 × 76-419 × 13 -584 Universal beams UB;

— 英标H型钢 UC152-356 × 152-406 × 23-1299 Universal columns UC;

— 斜缘工字钢 IPN80-600 J 76 -254× 76-203 × 13-82 Taper flange I sections IPN and J.Channels:

— 直缘槽钢 UPE 80-400 PFC 100-430 × 50 -100× 10-64 Parallel flange channels UPE and PFC;

— 斜缘槽钢 UPN50-400 U 40-65 × 20-42 × 4-5.5 CH 76-483 × 38-102 × 7-65 Taper flange channels UPN, U and CH.

4 分类和标记

4.1 分类

4.1.1 主要等级类别

此标准中所例举出的钢材的分类按照EN 10020中非合金优质钢的方法进行分类。

4.1.2组别和等级

此标准说明了八种钢材组别S 185,S 235,S 275,S 355,S 450,E 295,E 335和E 360。 其在机械性能上有所不同。钢材组别为S 235和S 275的等级型号是JR、J0和J2。钢材组别为S355的等级型号是JR、J0、J2和K2。钢材组别为S 450的等级型号是J0。不同的等级在其所要求的冲击功上不同。

4.2标记

4.2.1 标记应该按照EN 10025-1的要求规定。

注 曾用标记和EN 10025:1990和EN 10025:1990+A1:1993中的曾用标记列表见附录A,表A.1。

4.2.2 标记应该包括:

-标准号(EN 10025-2);

-钢材名称或者钢材牌号;钢材名称应包括:

-标记S(结构钢)或者E(工艺钢);

-厚度≤16mm的最低屈服强度的标识,用Mpa表示1);

-如果适用,关于冲击功数值的等级标记;

-如果适用,表示特殊操作的附加标记C(见表10、11、12和13)。

-标明“+N或者+AR” 当产品要求在+N或+AR条件下(见3.1、3.2和6.3)订货和供货时,其钢材牌号中应包括这样的标识“+N或+AR”。

示例 一种适于冷弯边(C)的结构钢(S),其在室温条件下的最低屈服强度为355Mpa1),在0℃(J0)条件下的最低冲击功数值为27J,供货状态为正火轧制(或者轧制状态)钢材EN 10025-2-S355J0C+N(或者+AR)或者钢材EN 10025-2-1.0554+N (或者+AR)

5.部分牌号的化学成分

|

牌号 |

化学成分(质量分数)/% |

||||||||

|

C |

Si |

Mn |

S、P |

Nb |

V |

N |

Cu |

CEV |

|

|

S235JR |

≤0.17 |

- |

≤1.40 |

≤0.035 |

- |

- |

≤0.012 |

≤0.55 |

≤0.35 |

|

S235J0 |

≤0.030 |

||||||||

|

S275JR |

≤0.21 |

- |

≤1.50 |

≤0.035 |

- |

- |

≤0.012 |

≤0.40 |

|

|

S275J0 |

≤0.18 |

≤0.030 |

|||||||

|

S355JR |

≤0.24 |

≤0.55 |

≤1.60 |

≤0.035 |

≤0.05 |

≤0.13 |

≤0.012 |

≤0.45 |

|

|

S355J0 |

≤0.20 |

≤0.030 |

|||||||

|

S355J2 |

≤0.025 |

- |

|||||||

|

S450J0 |

≤0.20 |

≤0.55 |

≤1.70 |

≤0.030 |

≤0.025 |

≤0.47 |

|||

6.部分牌号的力学性能和工艺性能

|

牌号 |

屈服强度ReH(MPa) 对厚度(mm) |

抗拉强度Rm (MPa) |

伸长率A (%) |

纵向冲击功KV |

||

|

≤16 |

>16~40 |

试验温度(℃) |

冲击功 (J) |

|||

|

S235JR |

≥245 |

≥235 |

360~510 |

≥26 |

20 |

≥27 |

|

S235J0 |

0 |

|||||

|

S275JR |

≥285 |

≥275 |

410~560 |

≥23 |

20 |

≥27 |

|

S275J0 |

0 |

≥27 |

||||

|

S355JR |

≥365 |

≥355 |

470~630 |

≥22 |

20 |

≥27 |

|

S355J0 |

0 |

≥27 |

||||

|

S355J2 |

-20 |

≥27 |

||||

|

S450J0 |

≥475 |

≥455 |

550~720 |

≥19 |

0 |

≥27 |

7.欧标H型钢HE系列规格尺寸如下:

|

型号 |

米重 kg/m |

规格 |

A cm2 |

|||

|

h mm |

b mm |

s mm |

t mm |

|||

|

HE 100 AA |

12.2 |

91.0 |

100.0 |

4.2 |

5.5 |

15.6 |

|

HE 100 A |

16.7 |

96.0 |

100.0 |

5.0 |

8.0 |

21.2 |

|

HE 100 B |

20.4 |

100.0 |

100.0 |

6.0 |

10.0 |

26.0 |

|

HE 100 C |

30.9 |

110.0 |

103.0 |

9.0 |

15.0 |

39.3 |

|

HE 100 M |

41.8 |

120.0 |

106.0 |

12.0 |

20.0 |

53.2 |

|

HE 120 AA |

14.6 |

109.0 |

120.0 |

4.2 |

5.5 |

18.6 |

|

HE 120 A |

19.9 |

114.0 |

120.0 |

5.0 |

8.0 |

25.3 |

|

HE 120 B |

26.7 |

120.0 |

120.0 |

6.5 |

11.0 |

34.0 |

|

HE 120 C |

39.2 |

130.0 |

123.0 |

9.5 |

16.0 |

49.9 |

|

HE 120 M |

52.1 |

140.0 |

126.0 |

12.5 |

21.0 |

66.4 |

|

HE 140 AA |

18.1 |

128.0 |

140.0 |

4.3 |

6.0 |

23.0 |

|

HE 140 A |

24.7 |

133.0 |

140.0 |

5.5 |

8.5 |

31.4 |

|

HE 140 B |

33.7 |

140.0 |

140.0 |

7.0 |

12.0 |

43.0 |

|

HE 140 C |

48.2 |

150.0 |

143.0 |

10.0 |

17.0 |

61.5 |

|

HE 140 M |

63.2 |

160.0 |

146.0 |

13.0 |

22.0 |

80.6 |

|

HE 160 AA |

23.8 |

148.0 |

160.0 |

4.5 |

7.0 |

30.4 |

|

HE 160 A |

30.4 |

152.0 |

160.0 |

6.0 |

9.0 |

38.8 |

|

HE 160 B |

42.6 |

160.0 |

160.0 |

8.0 |

13.0 |

54.3 |

|

HE 160 C |

59.2 |

170.0 |

163.0 |

11.0 |

18.0 |

75.4 |

|

HE 160 M |

76.2 |

180.0 |

166.0 |

14.0 |

23.0 |

97.1 |

|

HE 180 AA |

28.7 |

167.0 |

180.0 |

5.0 |

7.5 |

36.5 |

|

HE 180 A |

35.5 |

171.0 |

180.0 |

6.0 |

9.5 |

45.3 |

|

HE 180 B |

51.2 |

180.0 |

180.0 |

8.5 |

14.0 |

65.3 |

|

HE 180 C |

69.8 |

190.0 |

183.0 |

11.5 |

19.0 |

89.0 |

|

HE 180 M |

88.9 |

200.0 |

186.0 |

14.5 |

24.0 |

113.3 |

|

HE 200 AA |

34.6 |

186.0 |

200.0 |

5.5 |

8.0 |

44.1 |

|

HE 200 A |

42.3 |

190.0 |

200.0 |

6.5 |

10.0 |

53.8 |

|

HE 200 B |

61.3 |

200.0 |

200.0 |

9.0 |

15.0 |

78.1 |

|

HE 200 C |

81.9 |

210.0 |

203.0 |

12.0 |

20.0 |

104.4 |

|

HE 200 M |

103 |

220.0 |

206.0 |

15.0 |

25.0 |

131.3 |

|

HE 220 AA |

40.4 |

205.0 |

220.0 |

6.0 |

8.5 |

51.5 |

|

HE 220 A |

50.5 |

210.0 |

220.0 |

7.0 |

11.0 |

64.3 |

|

HE 220 B |

71.5 |

220.0 |

220.0 |

9.5 |

16.0 |

91.0 |

|

HE 220 C |

94.1 |

230.0 |

223.0 |

12.5 |

21.0 |

119.9 |

|

HE 220 M |

117 |

240.0 |

226.0 |

15.5 |

26.0 |

149.4 |

|

HE 240 AA |

47.4 |

224.0 |

240.0 |

6.5 |

9.0 |

60.4 |

|

HE 240 A |

60.3 |

230.0 |

240.0 |

7.5 |

12.0 |

76.8 |

|

HE 240 B |

83.2 |

240.0 |

240.0 |

10.0 |

17.0 |

106.0 |

|

HE 240 C |

119 |

255.0 |

244.0 |

14.0 |

24.5 |

152.2 |

|

HE 240 M |

157 |

270.0 |

248.0 |

18.0 |

32.0 |

199.6 |

|

HE 260 AA |

54.1 |

244.0 |

260.0 |

6.5 |

9.5 |

69.0 |

|

HE 260 A |

68.2 |

250.0 |

260.0 |

7.5 |

12.5 |

86.8 |

|

HE 260 B |

93.0 |

260.0 |

260.0 |

10.0 |

17.5 |

118.4 |

|

HE 260 C |

132 |

275.0 |

264.0 |

14.0 |

25.0 |

168.4 |

|

HE 260 M |

172 |

290.0 |

268.0 |

18.0 |

32.5 |

219.6 |

|

HE 280 AA |

61.2 |

264.0 |

280.0 |

7.0 |

10.0 |

78.0 |

|

HE 280 A |

76.4 |

270.0 |

280.0 |

8.0 |

13.0 |

97.3 |

|

HE 280 B |

103 |

280.0 |

280.0 |

10.5 |

18.0 |

131.4 |

|

HE 280 C |

145 |

295.0 |

284.0 |

14.5 |

25.5 |

185.2 |

|

HE 280 M |

189 |

310.0 |

288.0 |

18.5 |

33.0 |

240.2 |

|

HE 300 AA |

69.8 |

283.0 |

300.0 |

7.5 |

10.5 |

88.9 |

|

HE 300 A |

88.3 |

290.0 |

300.0 |

8.5 |

14.0 |

112.5 |

|

HE 300 B |

117 |

300.0 |

300.0 |

11.0 |

19.0 |

149.1 |

|

HE 300 C |

177 |

320.0 |

305.0 |

16.0 |

29.0 |

225.1 |

|

HE 300 M |

238 |

340.0 |

310.0 |

21.0 |

39.0 |

303.1 |

|

HE 320 AA |

74.2 |

301.0 |

300.0 |

8.0 |

11.0 |

94.6 |

|

HE 320 A |

97.6 |

310.0 |

300.0 |

9.0 |

15.5 |

124.4 |

|

HE 320 B |

127 |

320.0 |

300.0 |

11.5 |

20.5 |

161.3 |

|

HE 320 C |

186 |

340.0 |

305.0 |

16.0 |

30.5 |

236.9 |

|

HE 320 M |

245 |

359.0 |

309.0 |

21.0 |

40.0 |

312.0 |

|

HE 340 AA |

78.9 |

320.0 |

300.0 |

8.5 |

11.5 |

100.5 |

|

HE 340 A |

105 |

330.0 |

300.0 |

9.5 |

16.5 |

133.5 |

|

HE 340 B |

134 |

340.0 |

300.0 |

12.0 |

21.5 |

170.9 |

|

HE 340 M |

248 |

377.0 |

309.0 |

21.0 |

40.0 |

315.8 |

|

HE 360 AA |

83.7 |

339.0 |

300.0 |

9.0 |

12.0 |

106.6 |

|

HE 360 A |

112 |

350.0 |

300.0 |

10.0 |

17.5 |

142.8 |

|

HE 360 B |

142 |

360.0 |

300.0 |

12.5 |

22.5 |

180.6 |

|

HE 360 M |

250 |

395.0 |

308.0 |

21.0 |

40.0 |

318.8 |

|

HE 400 AA |

92.4 |

378.0 |

300.0 |

9.5 |

13.0 |

117.7 |

|

HE 400 A |

125 |

390.0 |

300.0 |

11.0 |

19.0 |

159.0 |

|

HE 400 B |

155 |

400.0 |

300.0 |

13.5 |

24.0 |

197.8 |

|

HE 400 M |

256 |

432.0 |

307.0 |

21.0 |

40.0 |

325.8 |

|

HE 450 AA |

99.7 |

425.0 |

300.0 |

10.0 |

13.5 |

127.1 |

|

HE 450 A |

140 |

440.0 |

300.0 |

11.5 |

21.0 |

178.0 |

|

HE 450 B |

171 |

450.0 |

300.0 |

14.0 |

26.0 |

218.0 |

|

HE 450 M |

263 |

478.0 |

307.0 |

21.0 |

40.0 |

335.4 |

|

HE 500 AA |

107 |

472.0 |

300.0 |

10.5 |

14.0 |

136.9 |

|

HE 500 A |

155 |

490.0 |

300.0 |

12.0 |

23.0 |

197.5 |

|

HE 500 B |

187 |

500.0 |

300.0 |

14.5 |

28.0 |

238.6 |

|

HE 500 M |

270 |

524.0 |

306.0 |

21.0 |

40.0 |

344.3 |

|

HE 550 AA |

120 |

522.0 |

300.0 |

11.5 |

15.0 |

152.8 |

|

HE 550 A |

166 |

540.0 |

300.0 |

12.5 |

24.0 |

211.8 |

|

HE 550 B |

199 |

550.0 |

300.0 |

15.0 |

29.0 |

254.1 |

|

HE 550 M |

278 |

572.0 |

306.0 |

21.0 |

40.0 |

354.4 |

|

HE 600 AA |

129 |

571.0 |

300.0 |

12.0 |

15.5 |

164.1 |

|

HE 600 A |

178 |

590.0 |

300.0 |

13.0 |

25.0 |

226.5 |

|

HE 600 B |

212 |

600.0 |

300.0 |

15.5 |

30.0 |

270.0 |

|

HE 600 M |

285 |

620.0 |

305.0 |

21.0 |

40.0 |

363.7 |

|

HE 600 × 337 |

337 |

632.0 |

310.0 |

25.5 |

46.0 |

429.2 |

|

HE 600 × 399 |

399 |

648.0 |

315.0 |

30.0 |

54.0 |

508.5 |

|

HE 650 AA |

138 |

620.0 |

300.0 |

12.5 |

16.0 |

175.8 |

|

HE 650 A |

190 |

640.0 |

300.0 |

13.5 |

26.0 |

241.6 |

|

HE 650 B |

225 |

650.0 |

300.0 |

16.0 |

31.0 |

286.3 |

|

HE 650 M |

293 |

668.0 |

305.0 |

21.0 |

40.0 |

373.7 |

|

HE 650 × 343 |

343 |

680.0 |

309.0 |

25.0 |

46.0 |

437.5 |

|

HE 650 × 407 |

407 |

696.0 |

314.0 |

29.5 |

54.0 |

518.8 |

|

HE 700 AA |

150 |

670.0 |

300.0 |

13.0 |

17.0 |

190.9 |

|

HE 700 A |

204 |

690.0 |

300.0 |

14.5 |

27.0 |

260.5 |

|

HE 700 B |

241 |

700.0 |

300.0 |

17.0 |

32.0 |

306.4 |

|

HE 700 M |

301 |

716.0 |

304.0 |

21.0 |

40.0 |

383.0 |

|

HE 700 × 352 |

352 |

728.0 |

308.0 |

25.0 |

46.0 |

448.6 |

|

HE 700 × 418 |

418 |

744.0 |

313.0 |

29.5 |

54.0 |

531.9 |

|

HE 800 AA |

172 |

770.0 |

300.0 |

14.0 |

18.0 |

218.5 |

|

HE 800 A |

224 |

790.0 |

300.0 |

15.0 |

28.0 |

285.8 |

|

HE 800 B |

262 |

800.0 |

300.0 |

17.5 |

33.0 |

334.2 |

|

HE 800 M |

317 |

814.0 |

303.0 |

21.0 |

40.0 |

404.3 |

|

HE 800 × 373 |

373 |

826.0 |

308.0 |

25.0 |

46.0 |

474.6 |

|

HE 800 × 444 |

444 |

842.0 |

313.0 |

30.0 |

54.0 |

566.0 |

|

HE 900 AA |

198 |

870.0 |

300.0 |

15.0 |

20.0 |

252.2 |

|

HE 900 A |

252 |

890.0 |

300.0 |

16.0 |

30.0 |

320.5 |

|

HE 900 B |

291 |

900.0 |

300.0 |

18.5 |

35.0 |

371.3 |

|

HE 900 M |

333 |

910.0 |

302.0 |

21.0 |

40.0 |

423.6 |

|

HE 900 × 391 |

391 |

922.0 |

307.0 |

25.0 |

46.0 |

497.7 |

|

HE 900 × 466 |

466 |

938.0 |

312.0 |

30.0 |

54.0 |

593.7 |

|

HE 1000 AA |

222 |

970.0 |

300.0 |

16.0 |

21.0 |

282.2 |

|

HE 1000 × 249 |

249 |

980.0 |

300.0 |

16.5 |

26.0 |

316.8 |

|

HE 1000 A |

272 |

990.0 |

300.0 |

16.5 |

31.0 |

346.8 |

|

HE 1000 B |

314 |

1000.0 |

300.0 |

19.0 |

36.0 |

400.0 |

|

HE 1000 M |

349 |

1008.0 |

302.0 |

21.0 |

40.0 |

444.2 |

|

HE 1000 × 393 |

393 |

1016.0 |

303.0 |

24.4 |

43.9 |

500.2 |

|

HE 1000 × 415 |

415 |

1020.0 |

304.0 |

26.0 |

46.0 |

528.7 |

|

HE 1000 × 438 |

438 |

1026.0 |

305.0 |

26.9 |

49.0 |

556.0 |

|

HE 1000 × 494 |

494 |

1036.0 |

309.0 |

31.0 |

54.0 |

629.1 |

|

HE 1000 × 584 |

584 |

1056.0 |

314.0 |

36.0 |

64.0 |

743.7 |